You might have been browsing around online, looking for information about precision measurement, and stumbled across mention of a gage R & R study. It can seem everywhere you turn, measurement experts mention gage R & R studies and how important they are to proper tool functioning. Well, what is a gage R & R study exactly? What importance does it serve? Why should you care about understanding gage R & R studies? We at Higher Precision would be glad to walk you through the details of this very important technique.

First of all, let’s define what R & R stands for. R & R refers to repeatability and reproducibility. Repeatability is the amount of variation seen in a measurement when one individual measures one item with one gage. Reproducibility is the amount of variation seen in a measurement done by different individuals measuring one item with one gage. Where repeatability assesses variation that is due to the equipment, or gage, being used to measure, reproducibility assesses variation that is due to the operators utilizing that gage. Gage R & R studies intend to find all of the variability within the measurement context in order to determine what parts of that process demand adjustment or whether the measurement has an appropriate amount of variation.

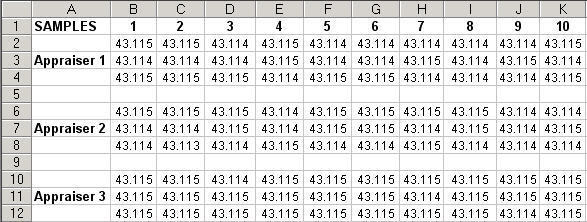

The total variation seen in a measurement can come from 3 central sources: 1) the part being measured, 2) the operator doing the measuring, or 3) the gage used to complete the measurement. The gage R & R study is therefore an excellent way to root out the source of error and to find a solution. The general set up of a gage R & R study is as follows. Take a set number of operators and a set number of parts to measure. The operators doing the measuring can be individuals who work in production, inspectors, or lab technicians, they simply need to understand how to use the gage. Then, each operator uses one gage to measure each part a set number of times. This process results in a structured group of data to analyze, where each operator has measured each part numerous times. Running the data from a gage R & R study can be done through a few of different methods. There is the long AIAG method, the short AIAG method, and then analysis of variance, or ANOVA. When there is a statistical software package available, the ANOVA is the most trustworthy way to run your data.

The gage R & R study is an invaluable tool for assessing the variation within a particular measurement system that includes the part being measured, the tool making the measurement, and the person doing the measuring. In the world of precision measurement, you have to know that you can trust your production line, and running regular gage R & R studies is the best way to guarantee exactitude. Running a gage R & R study allows you to assess whether there is an inappropriate about of variation with your process, and then to determine whether the reproducibility or repeatability is to blame. Measurement system variation and gage R & R studies are pivotal to any well-run precision measurement process.