Calipers are amazing little precision measurement tools. With four distinct ways to measure, they provide incredible utility in measuring inside and outside diameter, depth, and step.

Whether it’s an electronic, dial, or Vernier – any and all calipers are capable of each of these measurements.

We’ll walk you through each of these measurement techniques so that you are well-versed in the capabilities of your caliper.

Understanding the Layout of Caliper Tools

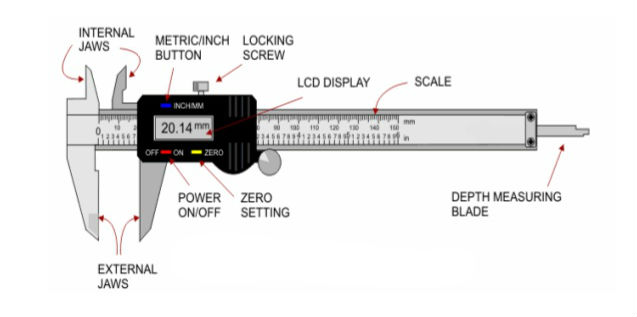

A basic caliper is made of seven different parts:

- Upper jaws

- Lower jaws

- Lock Screw

- Thumb Screw

- Vernier Scale

- Main Scale

- Depth Rod

Depending on whether your caliper is manual or digital, you may have a readout screen that tells you a particular measurement. Alternatively, some calipers require reading the displayed scales for an accurate measurement.

For measurement purposes, both the upper and lower jaw sets consist of one fixed jaw and one sliding jaw.

Before completing any measurement, it’s important to ensure that your caliper is set to a zero point. If your tool is even the slightest bit off from the zero point, your final measurement will be inaccurate.

Setting Your Caliper to Zero

To set your caliper tool to a zero point:

- Open the jaws of the caliper

- Thoroughly clean in between the tool’s jaw

- Properly close the jaws again

- At this point, the readout should be 0.00. With an electronic caliper, you may have to reset the zero button.

4 Ways to Measure with Calipers

Depending on the purpose of using this tool, there are many different ways to find measurements using calipers. Here are some of the ways to measure with calipers:

Measuring the Outside Diameter with Calipers

Let’s start with outside diameter measurement.

The simplest of all the caliper measurements, outside measurement involves measuring the outside surface of an object. When you’re looking to measure the outside diameter of an object, consider these steps:

- Take the object you need to measure and open the lower jaws of the caliper.

- Next, close the jaws gently around the object.

- With the jaws closed shut on the object, simply read the measurement from the digital screen or on the manual scale.

- Remember to make sure your caliper is perpendicular to the object you are measuring, and that there is no dirt or residue on the jaws that could invalidate the number.

Measuring the Inside Diameter with Calipers

The second type of measurement is inside measurement. For inside measurements of an object, you will use the upper, smaller jaws of your caliper.

- Start by closing the upper jaws and placing them into whatever space you are measuring.

- Next, slowly open the jaws until they are pressed against the edge of the inside surface.

- Once the jaws are pressed against the edge of the space, you can read off the measurement listed.

- Again, make sure that the caliper is properly lined up with the object for accurate results!

Finding the Depth Measurement with Calipers

The third type of measurement you can accomplish with a caliper is called depth measurement. Depth measurement is used for determining the size of a particular hole.

For this purpose, you will use the depth rod at the end of the caliper.

- Simply put the machined end of your caliper at the top of the hole you are measuring

- Extend the depth rod until it makes contact with the bottom of the hole.

- Read off the measurement.

- Double-check that you are holding the caliper parallel to the hole you are measuring, as any off angle could give you a false measurement.

Finding the Step Measurement with Calipers

Finally, the fourth type of caliper measurement is a step measurement. A slightly more complex and lesser-known technique, step measurement can be very useful for a variety of measurements.

- Start by placing the sliding jaw of the caliper on the upper step of the object you are measuring. Leave the caliper just slightly open.

- Slowly begin to open the caliper further until the fixed jaw hits against the lower step of the object.

- Then read off the measurement and voila!

Determining Caliper Measurements with Higher Precision

Calipers are a necessary tool for any successful precision measurement toolbox. These handy little devices are capable of four separate measurements, each designed with distinct utility. Calipers can be used to conduct outside or inside diameter, depth, and step measurements.

Depending on the types of measurements you’re looking for, you may use one or two of these more than others. However, having an understanding of all a caliper’s measurement tricks will help you be equipped to handle any measurement needed.