Gage block, gage blocks, gage blocks. You know them, you love them, you cannot live without them. But how do you decide between steel and ceramic gage blocks? How do you tell which material is best suited to the metrology work you do? Today we will try to tackle the age-old question of what type of gage block is best. Spoiler alert—they both have advantages based on the measurement application. However, understanding the differences between steel and ceramic gage blocks will help you navigate choosing between them. So settle in while we talk about gage blocks.

Gage Block Overview

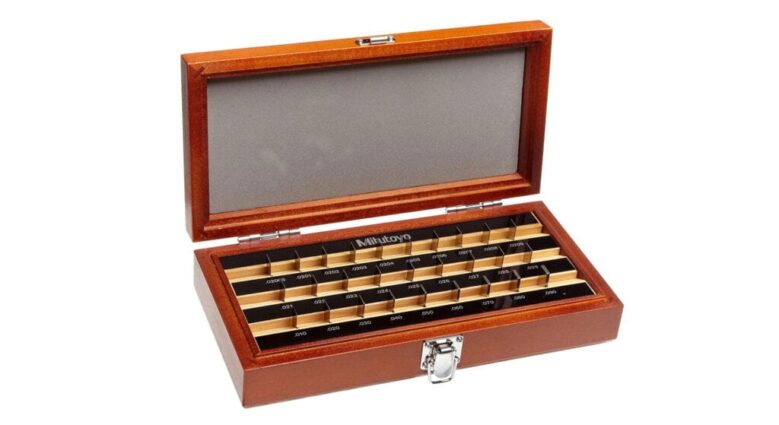

The Higher Precision team has written about gage blocks a lot over the years, but it is always helpful to start with a quick overview to orient our reader to the topic. Gage blocks were originally invented by Carl Edvard Johansson as a way to solve the problem of needing different tools to take differently sized measurements. Essentially, gage blocks allow for various combinations that help streamline measurements of all sizes using a single gage. Sold commonly as a gage block set, these helpful devices can be combined in any number of ways to make gage measurement simple and straightforward. Since they are designed in standard lengths, gage blocks help increase the accessibility of different measurement settings.

The Wringing Process for Gage Blocks

Wringing is a process completed with two or more gage blocks in which the gage blocks are slid together in such a way that the face of one gage block becomes bonded to the other. Wringing allows for the combination of gage blocks from a set to create a range of block sizes. Since a gage block is designed with an ultra-flat face surface and precisely parallel sides it is capable of a tight adherence to other gage blocks. Wringing results from a combination of air pressure, surface tension, and molecular attraction. The steps to wring two gage blocks to each other are as follows: 1) Wipe a gage block with an oiled pad, making sure to remove any extra oil from the block with a dry pad afterwards, 2) Slide the gage block perpendicularly across a second gage block while applying pressure until they are perpendicular with four equal extensions in a cross-like shape, and 3) Rotate the gage block until it is lined up as parallel to the second gage block. Wringability refers to the ability of two gage blocks to adhere tightly to each other without external means.

Grades of Gage Blocks

Gage blocks come in different grades and grade is determined by the tightness of the tolerance given the size. The higher the gage block grade, the higher and tighter the tolerance, resulting in a higher level of measurement accuracy and precision. There are a number of ways to denote the grade of a gage block that differ slightly around the world. Some label the grade from high to low tolerance using letters (AAA, AA, A, B), numbers (0.5, 1, 2, 3), or a combination (00, 0, AS-1, AS-2, K). Always make sure you understand which grading system you are working with. Within each gage block grade, there can be variations in tolerance levels, depending on whether the gage block is made of steel or ceramic. This variance in tolerance present in gage blocks is one of the most important reasons to understand the differences between steel gage blocks and ceramic gage blocks.

Steel Gage Blocks

Steel gage blocks are the most common type of gage block on the market. An advantage of steel is that many industrial products are also made of steel, making the measurement tool and measurement piece more aligned when collecting measurement data. Having your gage blocks be made of the same material as the parts or products being measured plays an important role regarding thermal expansion, eliminating the need for a thermometer due to the similar behavior of both materials. Steel itself is a sturdy material that can withstand the lapping process and ongoing use without the risk of damage. The smooth properties of steel gage blocks also make them well-suited to successful wringing when completing measurements. Another advantage of steel gage blocks is that they are generally inexpensive to purchase and replace. However, they are susceptible to corrosion over time, requiring more regular replacement than their ceramic counterpart.

Ceramic Gage Blocks

Ceramic gage blocks are the less common than steel gage blocks. One advantage of the ceramic material is that the thermal expansion coefficient is close to zero. This means that external stable temperature or external changes in temperature will have a minimal effect on the size of a ceramic gage block. Additionally, ceramic gage blocks have a zero phase shift, increasing the dependability of measurements completed using them. The ceramic material also prevents scratching as well as corrosion over time, helping these gage blocks last despite a higher cost up front. The major disadvantage of ceramic gage blocks is that they are more easily damaged than their steel counterparts. When a ceramic gage block is dropped or hit with another tool accidentally it is more likely to crack, chip, or be damaged in some way.

Steel Gage Blocks Versus Ceramic Gage Blocks

The material used to make a gage block will have important outcomes on durability, measurement ease, and reactions to temperature changes. Steel gage blocks and ceramic gage blocks each come with advantages and disadvantages. If you are having a difficult time deciding, owning a set of both could help account for their differences. In general, steel gage blocks are damage-resistant, matched in thermal expansion to many products, and provide a high level of accuracy with every measurement. Ceramic gage blocks are resistant to corrosion and wear over the long-term, have a thermal expansion coefficient that is almost zero, and come with zero phase shift. Gage blocks in general are a must-have tool, and both steel gage blocks and ceramic gage blocks have clear and distinct advantages. The most important consideration is which gage block material will work best with the measurement context you work in.

Conclusion

At Higher Precision, we know about gage blocks. We sell both steel gage blocks and ceramic gage blocks with the support of a number of trusted brands. If you have questions or concerns about which type of gage block material is best suited to your needs, contact us today to speak with a metrology expert.

FREQUENTLY ASKED QUESTIONS

- What are the advantages of using steel gage blocks?

Steel gage blocks are the most commonly sold type of gage block available. Part of their popularity is their ability to resist damage that can befall ceramic gage blocks more easily. Steel is a very hard and tough material, so dropping a steel gage block or another tool or object hitting it is not likely to cause damage. Steel gage blocks, however, are susceptible to corrosion and wear over longer periods of time. One advantage despite their susceptibility to long-term wear is that steel gage blocks are cheaper to buy initially and therefore cheaper to replace. Furthermore, steel is a common material found across parts, tools, and objects. This means that steel gage blocks are often made of the same material as the product they are being used to measure, which means they will have the same degree of thermal expansion as those products. Steel gage blocks are precise and highly accurate, increasing how often they are the gage block of choice.

- What are the advantages of using ceramic gage blocks?

While not as common as steel gage blocks, ceramic gage blocks come with a number of advantages depending on the types of measurements you need them for. Ceramic gage blocks have both a thermal expansion coefficient that is almost zero and a zero phase shift. This makes ceramic gage blocks well suited to measurements that may be influenced by changes in temperature. Any temperature changes within the measurement lab will have a minimal effect on ceramic gage blocks, increasing their reliability and dependability. Additionally, ceramic gage blocks last almost forever. Due to the ceramic material, ceramic gage blocks have a high resistance to corrosion over time. While they are more expensive than steel gage blocks initially, ceramic gage blocks will not fall victim to the test of time. One important limitation of ceramic gage blocks to consider, however, is their risk of damage. While they resist corrosion, dropping a ceramic gage block or hitting it with another object has a chance of cracking, chipping, or damaging the ceramic.

- What is the wringing process for steel gage blocks and ceramic gage blocks?

Wringing refers to a process of adhering one gage block to another in order to create a larger block that helps adjust the size of a product for a measurement. Wring-ability refers to the degree that two gage blocks are able to be wrung to each other with a sturdy hold. The process to wring two gage blocks together is simple to complete. First, the surface of a gage block that will come into contact with another gage block is lightly oiled. Second, one gage block is slid across a second in a perpendicular direction while applying pressure. Third, the gage block is turned while continuing to apply pressure until it is aligned parallel to the other gage block. At this point the two gage blocks should be bound together through forces of air pressure, molecular attraction, and surface tension. Wringing can be completed with steel gage blocks and ceramic gage blocks alike, but must always be done with two gage blocks of the same material. While wringing is done slightly more effectively with steel gage blocks due to the chemical properties of steel, it can also be done with ceramic gage blocks when needed.

GLOSSARY TERMS

- Steel Gage Block

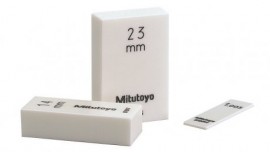

A steel gage block is a measurement tool used to accommodate different sized products using a single measurement device. Steel gage blocks allow for precise sizing adjustment during gage measurements. Steel gage blocks are rectangular blocks made out of steel that can be combined in a number of ways to accommodate different gage measurements. Steel gage blocks have a number of advantages including their high level of accuracy, their ability to match a number of products also made of steel in thermal expansion properties, and their resistance to damage.

- Ceramic Gage Block

A ceramic gage block is a measurement tool used to accommodate different sized products using a single measurement device. Ceramic gage blocks allow for precise sizing adjustment during gage measurements. Ceramic gage blocks are rectangular blocks made out of ceramic that can be combined in a number of ways to accommodate different gage measurements. The advantages of ceramic gage blocks include a near-zero thermal expansion coefficient, a zero phase shift, and resistance to wear and corrosion.

- Wringing

Wringing involves sliding two ceramic gage blocks or steel gage blocks together to make them adhere to one another in the process of measurement. Wringing occurs because of molecular attraction between the gage blocks resulting from air pressure and surface tension. In order to wring together two ceramic gage blocks or steel gage blocks you simply slightly oil the surface of the gage block, slide it perpendicularly across a second gage block while applying pressure, and rotate the gage block while applying further pressure until it is aligned in a parallel manner with the second gage block.