We have all heard of the good old fashioned micrometer. Furthermore, many of us have probably heard of the latest version of the micrometer, the laser scan micrometer. But what exactly is the laser scan micrometer? How does it function and what is it used for? It certainly sounds high tech to be using lasers to complete precision measurements, but the specific advantages and benefits of doing so are less clear. Today we are going to provide you with a general overview of laser scan micrometers and try to answer some of the questions about how they work to demystify these incredible precision measurement tools.

The operating principle behind a laser scan micrometer sounds complex, but uses basic principles of optic distortion. The laser built into a laser scan micrometer sends out a rotating optical beam that is then reflected or refracted by the obstructing object, the object being measured. There is both the originating rotating beam as well as a receiver located opposite the laser source. By blocking a certain amount of area in the laser path, the object being measured interrupts the light from the laser, making a shadow which represents the size of the object based on the length of time of the obstruction. Technology on the receiver collects data regarding the portion of the laser beam that is not obstructed by the object and focuses it onto a photocell. The photocell output can then be analyzed to determine the timing of the obstruction thus identifying the edges of the object. Built-in technology then computes a measurement from the laser and timing data. The rotating laser beam may originate from a mirror, a prism, a hologram, a tuning fork, or another mechanism, depending on the particular built of the laser scan micrometer. Thus, using a scanning laser that crosses an obstructing object, a measurement of that object can be taken based on the resulting behavior of the laser as it does or does not cross to the receiving end of the micrometer and the timed shadow that results.

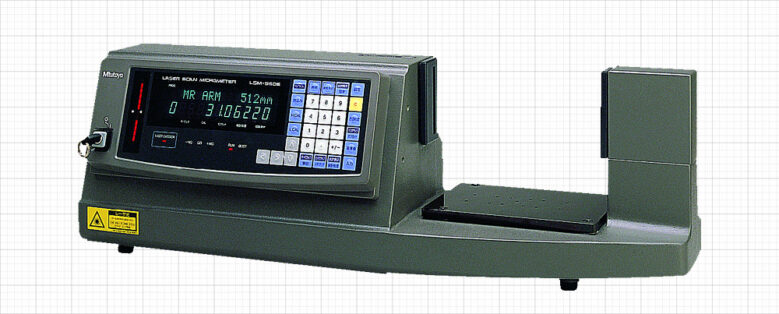

In general, laser scan micrometers are known for having a high scanning rate and a high level of accuracy as non-contact measurement tools, making them excellent for working with fragile workpieces at high temperatures, even when the objects being measured are vibrating or in motion. There are four main varieties of laser scan micrometer, and these include: automatic (also known as inline), bench-top (also known as floor), handheld (also known as portable), and machine-mounted. Laser scan micrometers come in a range of sizes, and may have an integrated display or a separate display unit. Additionally, most laser scan micrometers can be purchased alongside optional accessories that enhance the precision measurement task at hand including a calibration gage set, a workstage, an adjustable workstage, a wire guiding pulley, extension signal cables, extension relay cables, air-screen covers, or air-blow covers.

Laser scan micrometers are incredibly versatile and are used to complete highly accurate measurements across a range of settings. Some of the more standard measurements taken with laser scan micrometers include: in-line glass fiber or fine wire diameter, outer diameter of opaque or transparent cylinders, outer diameter and roundness of cylinders, X- and Y-axis electric cables and fibers, thickness of film and sheet, spacing of IC chip leads, gaps between rollers, film sheet thickness, disk head movement, taper and form, tape width, outer diameter of optical connector and ferrule, and serving as a dual system for measuring a larger outside diameter. The classic micrometer is a must-have tool for any metrologist. Newer, laser scan micrometers are a great addition to any precision measurement workspace. These optics-based precision tools complete excellent measurements and use the latest technology to reach amazing levels of accuracy.

Shop our Laser Scan Micrometers