Since 1969, the Sylvac metrology company has been producing incredible precision measurement tools and systems. Newer to the collection of digital measurement instruments, Sylvac now offers a range of optical scan machines. The family of scans designed and produced by Sylvac is made up of well-made machines that provide precise optical measurements for a variety of parts. Taking fast measurements of cylindrical parts has never been easier, with over 150 measurement features available. The Sylvac scans take control of even the most demanding part dimensions. No geometrical tolerance is too complex for these optical measurement machines.

Uses for Sylvac scans

The Sylvac scans are specially designed to take measurements of cylindrical parts. Because of the challenging dimensions and sizes involved when working with circular objects, precision and accuracy can sometimes be compromised. Now with the new family of Sylvac scans, measuring cylindrical objects is no longer a problem. These devices are intended to measure diameters anywhere from 0.2mm to 64mm and lengths of up to 500mm. There are no scans that compete. Aerospace shafts, CNC turned parts, automotive components, dental screws, connectors, metal packaging, hydraulic parts, dental implants, turbine parts, and rollers are just some of the objects that can be precisely measured using Sylvac scans. Finally, these devices can be used to analyze thread types of all sorts and different thread features.

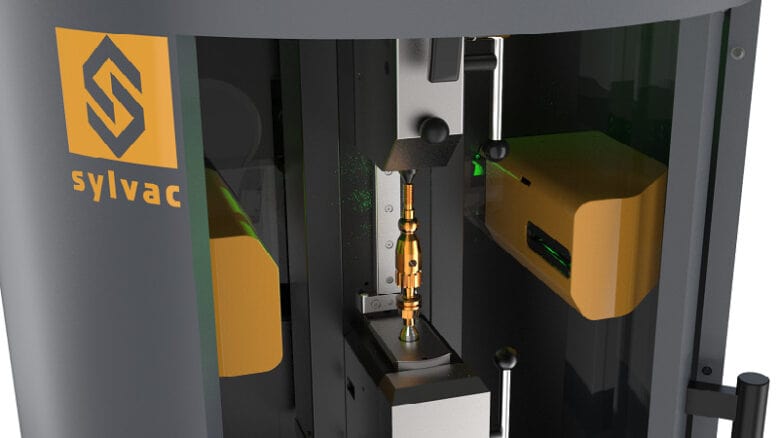

The measurement mechanism of Sylvac scans

The mechanism behind the measurements taken with Sylvac scans includes a light beam and a high level camera lens. Every scan made by Sylvac includes a green LED illuminator that projects a collimated light beam. This beam is projected across the part being measured and scanned at a speed of up to 100mm per second. The bi-telecentric lens system on the high resolution line-scan camera collects precise information regarding the contour of the cylindrical part. Then, the line-scan camera built into the device detects the projected image using a 200-megapixel camera lens. Once the image is collected, the contour of the part is reproduced on the associated software. Different elements of the part are precisely measured whether in a dynamic state or static state, with the part being rotated or not, respectively. This allows for straightforward measurement of run-out as well as concentricity.

What is the Sylvac-Reflex Scan operating principle?

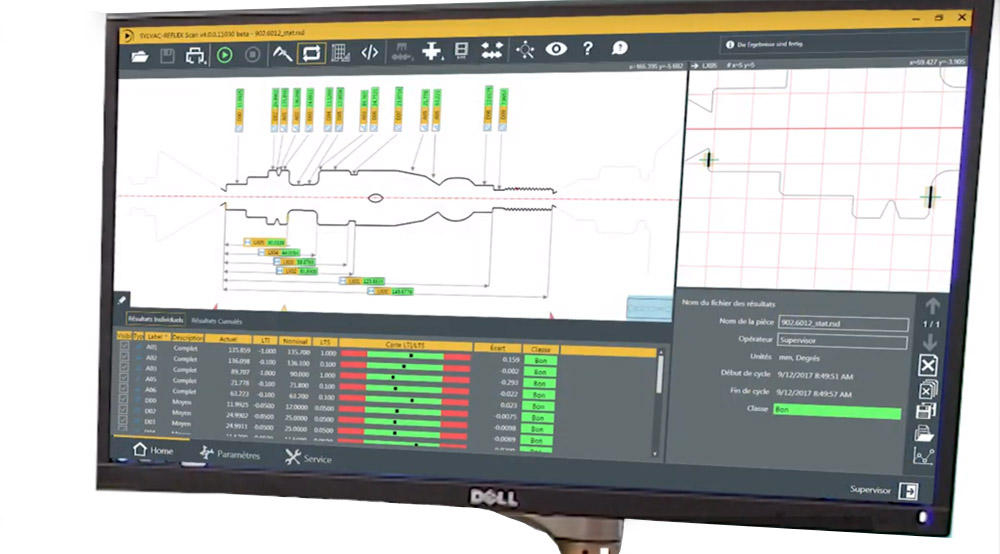

The Sylvac-Reflex SCAN software

Each scan made by Sylvac comes equipped with the Reflect SCAN software. The Reflex-SCAN software is easy to use, increases the flexibility of the device, and allows for multi-gauging as opposed to conventional measuring. The Sylvac Reflex-SCAN software works using the following steps: 1) The operated puts the part onto the scan, 2) The operator clicks the measurement button, 3) The part is then scanned, the main values are measured and displayed within the software against the generated part drawing, and 4) The operator can then choose to use the values as measured or to edit the automatic programming to measure within a particular classification (after entry of nominal and tolerance information). Furthermore, each Sylvac scan utilizes automatic recognition of existing parts and programs. What this means in practice is that at the push of a button you can complete repeat work. The device simply scans the part, recognizes the part, then loads and executes the measurements according the what the programs has stored from previous use.

Flexible report editor and statistic view

Sylvac scan technology comes with a flexible report editor. When building a presentation of all your completed measurements, you can customize the finalized report through addition of information. Using a straightforward drag and drop method, you are able to edit your reports in a customized fashion efficiently and easily. The available statistical view displays your measurement results trend through either a full screen report or a tooltip. The Sylvac scan statistic view allows for quick and easy analysis of all of your collected measurements. (The statistic view is only available on the Sylvac Scan F60.)

Statistical process control

Statistical process control (SPC) refers to the option of using your own statistical processes when analyzing the measurement data collected using the Sylvac scan. Each Sylvac scan device comes pre-equipped with main statistical calculation capability as a standardized feature, but you may want to use a preferred SPC software package. Sylvac offers a number of different export formats that allows you to import any measurement data collected with the Sylvac scan into your own statistical system. SPC software may come with the added benefit of additional applications that the Sylvac scan is unable to perform on its own, such as internal diameter measurements. SPC software allows for the application of measurements taken using complementary products and integrates them into the same report as the data collected from the Sylvac can. SPC software also usually provides the following features: histograms, control charts, graphics with limits, statistical parameters, and protocols.

What sets the Sylvac scans apart?

Every Sylvac scan is Swiss made and comes with the Swiss-made guarantee of quality and incredible precision. These devices are shop-hardened, ready to be used in any workshop environment that you need them in. Accuracy and performance are maintained using built-in calibration masters, maintaining any specifications and withstanding any changes in temperature. These tools are intended to be used close to the machine-tool and are appropriate for first-off part, sampling inspection, 100% inspection, and control in process (SPC). When you use a Sylvac scan, you are revolutionizing your precision measurement capabilities through reduced inspection time, reduced scrap, increased productivity, saved money, and quick investment return.

The Sylvac scan investment

Sylvac understands that when you make a precision measurement tool purchase, you want to make an informed and sensible decision. Metrology tools can be expensive and most of us want a device that will last and give us the most precise and accurate measurements possible. With this in mind, Sylvac offers an interface that helps project your estimated payback time directly calculated using your personal profile and expected Sylvac scan use. The majority of customers pay back within 6 months. The company will help set you up with a local agent to calculate your ROI and to provide you with any information you require to make a confident purchase. Beyond this service, the Sylvac scan functions with a number of optimal investment features. The traditional manual methods for taking measurements using multiple gauges results in up to 30 minutes of inspections time, whereas the Sylvac scan series allows for inspection times of 30 to 60 seconds. This will result in amazing cost reductions.

Sylvac scan applications

The beauty of the Sylvac scan family is that these incredible devices can be applied across a range of settings. The measurement of cylindrical parts comes with added challenges that are not associated with non-cylindrical measurements. Because of this added difficulty, you want your Sylvac scan to take care of the challenges for you. Each of the Sylvac scans offered provides reliable and precise measurement capability. These tools can be used in a range of applications including: automotive, aerospace, pharmaceuticals, electronic motors, packaging manufacturing, medical devices, the watch industry, plastics production, thread creation, connectors, munitions, injection moulding supply, cosmetics, plumbing, hydraulics, pneumatics, and more.

What specific models of Sylvac Scans are available?

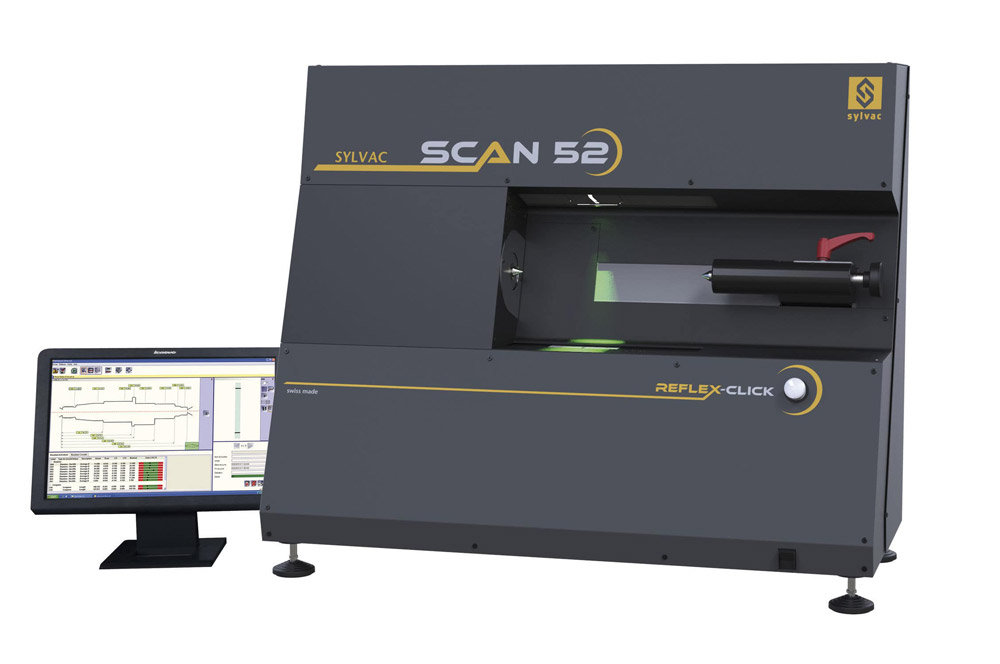

The Sylvac Scan 52 Reflex Click

The Sylvac Scan 52 Reflex Click is one of the top models of Sylvac scans available. Designed specifically with the goal of measuring standard and common cylindrical parts, the Sylvac Scan 52 Reflex Click is used across a wide range of settings and for various purposes. This scan is very simple to use with one-click measurement as the central mechanism. The Sylvac Scan 52 Reflex Click is built with a landscape design, uses an integrated calibration master, is built with reflex click technology, has data export capabilities, comes with SPC basic, and is accessible to anyone. In every Sylvac Scan 52 Reflex Click package you receive the instrument itself with all technical specifications, 2 male centers, Sylvac Reflex-SCAN software, a manual, and a rotary headstock. All you need to complete the set-up is a computer with a Windows multilingual operating system, a mouse, a keyboard, and a screen.

The Sylvac Scan 52 Reflex Click comes in two models, both sharing a measurement range of 0.5 + 52mm diameter and 300mm length, a resolution of 0.00001mm diameter and 0.0005mm length, accuracy of 1.5 + D/100μm diameter and 4 + L/100μm length, repeatability of 0.6μm diameter and 2.5μm length, a maximum part weight of 4kg, and a total weight of 103kg. The 902.5520—Scan52 model does not come with the rotary headstock. The 902.5521—Scan52 R does come with a rotary headstock.

The Sylvac Scan F60 and F60T

When working with parts that are more complex in build, you may benefit from utilizing one of the Sylvac Scan F60 or Sylvac Scan F60T models. These devices are made to handle splined, geared, interrupted, or threaded parts and in general provide an upgraded level of precision for standard cylindrical parts. The Sylvac Scan F60 or Sylvac Scan F60T models use a single pass rapid scan of 100mm per second, have quick release tooling, use a large LED status light, come with a safety light curtain, include a door to protect cleanliness, use live image view, have reflex click technology, and come with optional custom scripts. With an integrated calibration master and temperature sensors to maintain environmental control, tilt axis for advanced thread measurement, advanced software features, dust filtering to protect parts from contamination, and a statistics view, these devices are truly the best of the best.

The Sylvac Scan F60 and the Sylvac Scan F60T come in four models, all sharing a resolution of 0.00001mm, accuracy of 1 + D/100μm diameter and 3 + L/100μm length, repeatability of 0.5μm diameter and 2μm length, and a maximum part weight of 10kg. The 902.4060—SCAN F60 and the 902.4065—SCAN F60T models come with a measurement range of 0.2 + 64mm diameter and 300mm length, as well as a total weight of 235kg. The 902.4062—SCAN F60L and 902.4067—SCAN F60LT models come with a measurement range of 0.2 + 64mm diameter and 500mm length, as well as a total weight of 261kg. The 902.4065—SCAN F60T and the 902.4067—SCAN F60LT models also have a 30° tilting capability for thread measurements. These machines also come available with the Reflex-SCAN+ software. While the standard Sylvac Reflex-SCAN software comes with automatic measurement of diameters/lengths/angles/radii, automatic parts and program recognition, reports editor, data export, SPC basic calculations, SPC software on request, and 1 level of access management security, the Sylvac Reflex-SCAN+ software includes all of these features and also offers off-line programming, advanced dust filtering, statistics view, CAD import, an optional script function, and multiple levels of access management security.

Conclusion

The new family of Sylvac scans is revolutionizing the world of cylindrical part measurement. These digital optical scan machines are designed and produced by Sylvac to provide precise optical measurements across a range of parts in a range of settings. Providing fast, precise, and simple measurements of cylindrical parts has never been more readily available. The Sylvac scans can handle the most complex geometrical tolerance and demanding part dimensions. Talk to a representative at Higher Precision today about how one of the new Sylvac scans can change your life.

Watch a video on the Scan F60T

FREQUENTLY ASKED QUESTIONS

- What is the Sylvac Scan 52 Reflex Click and what is it used for?

There are two central designs of Sylvac scan and the Sylvac Scan 52 Reflex Click is one of them. The Sylvac Scan Reflex Click model is designed to complete common measurements of cylindrical parts. If you are in the market for a standard tool for standard work, then this is the Sylvac scan for you. In all settings, the Sylvac Scan 52 Reflex Click utilizes the simple power of one-click measurement. Equipped with an integrated calibration master, SPC basic, reflex click technology, data export capabilities, and a landscape design, the Sylvac Scan 52 Reflex Click is accessible to anyone and any workshop. The Sylvac Scan 52 Reflex Click only requires a computer with a Windows multilingual operating system, a mouse, a keyboard, and a display screen. Each scan package includes a manual, the Sylvac Reflex-SCAN software, two male centers, and a rotary headstock.

- What sets the Sylvac Scan F60 and F60T models apart from other Sylvac scans?

The Sylvac Scan F60 and Sylvac Scan F60T models go above and beyond the standard measurement capabilities of the Sylvac Scan 52 Reflex Click. The Sylvac Scan F60 and Sylvac Scan F60T are designed with complex parts in mind and can take precise measurements from geared, threaded, splined, or interrupted parts. These scans come with a large range of top-notch features including: tilt axis for advanced thread measurement, a statistics view, an integrated calibration master and temperature sensors to maintain environmental control, a safety light curtain, a single pass rapid scan of 100mm per second, reflex click technology, quick release tooling, dust filtering to protect parts from contamination, advanced software features, a door to protect cleanliness, a large LED status light, live image view, and custom optional scripts.

- What is the investment made when purchasing a Sylvac scan?

When you purchase a Sylvac scan, you are making a long-term investment. Sylvac understands that this can feel like a big undertaking and wants to set you up to have confidence in the purchase you make because they have confidence in the tools they make. Sylvac offers each customer the use of their estimated payback time interface. This calculating tool helps you to accurately determine how long your payback will take while factoring in the company or your personal profile and the expected amount of use for the Sylvac scan. Additionally, your measurement improvements will be worth the investment you make in a Sylvac scan. These devices can complete an inspection in only 30 to 60 seconds, compared to the 10 to 30 minutes of inspection time needed for other tools.

- What are some of the applications for the Sylvac scan devices?

All of the Sylvac scans supply an operator with a wide range of application options. These devices are designed to measure cylindrical parts, and cylindrical part measurements are relevant across a range of fields. A few specific field applications include: injection moulding supply, automotive, cosmetics, aerospace, pneumatics, pharmaceuticals, packaging manufacturing, medical devices, plastics production, thread creation, connectors, munitions, the watch industry, plumbing, hydraulics, and electronic motors. The challenges present when taking cylindrical measurements are all taken care of when using the Sylvac scans.

GLOSSARY TERMS

- Sylvac Scan

A Sylvac scan is a measurement device built to take accurate and precise measurements of cylindrically shaped parts and objects. The new family of Sylvac scans solves the challenges normally associated with cylindrical measurements. Capable of measuring diameters anywhere from 0.2mm to 64mm and lengths of up to 500mm, you will not find another scan like it. Some examples of parts that can be successfully measured using the Sylvac scans include: roller, turbine parts, dental implants, hydraulic parts, mental packaging, connectors, dental screws, automotive components, CNC turned parts, and aerospace shafts.

- The Sylvac Scan 52 Reflex Click

The Sylvac Scan 52 Reflex Click is one subcategory of the new family of Sylvac scans and it comes in two models: the 902.5520—Scan52 and the 902.5521—Scan52 R. Both models share a measurement range of 0.5 + 52mm diameter and 300mm length, a resolution of 0.00001mm diameter and 0.0005mm length, accuracy of 1.5 + D/100μm diameter and 4 + L/100μm length, repeatability of 0.6μm diameter and 2.5μm length, a maximum part weight of 4kg, and a total weight of 103kg. The 902.5520—Scan52 model does not come with the rotary headstock. The 902.5521—Scan52 R does come with a rotary headstock.

- The Sylvac Scan F60 and F60T

The Sylvac Scan F60 and F60T make up a subcategory of the new family of Sylvac scans and come in four models: the 902.4060—SCAN F60, the 902.4065—SCAN F60T, the 902.4062—SCAN F60L, and the 902.4067—SCAN F60LT. All models share a resolution of 0.00001mm, accuracy of 1 + D/100μm diameter and 3 + L/100μm length, repeatability of 0.5μm diameter and 2μm length, and a maximum part weight of 10kg. The 902.4060—SCAN F60 and the 902.4065—SCAN F60T models come with a measurement range of 0.2 + 64mm diameter and 300mm length, as well as a total weight of 235kg. The 902.4062—SCAN F60L and 902.4067—SCAN F60LT models come with a measurement range of 0.2 + 64mm diameter and 500mm length, as well as a total weight of 261kg. The 902.4065—SCAN F60T and the 902.4067—SCAN F60LT models also have a 30° tilting capability for thread measurements. These machines also come available with the Reflex-SCAN+ software.