A caliper gage is a measurement tool used to determine the distance between two opposite points on a part or object. Caliper gages come in dial or digital designs and can be specifically made to measure the inside or the outside diameter of an object. Today, we will provide you with an overview of how caliper gages work, their different forms and purposes, and their degree of accuracy.

What is a Caliper Gage: The Basics

While the accuracy of a caliper gage changes a bit based on the type of gage and the measurement being taken, these tools are generally well-known for their high levels of accuracy and their intuitive usage.

General Types of Caliper Gages

- Dial caliper gage

- Digital caliper gage

- Internal caliper gage

- External caliper gage

- Inch caliper gage

- Metric caliper gage

Advantages and Disadvantages of Caliper Gages

The caliper gage is an incredibly versatile tool that can be used across a number of contexts, making it one of the most commonly owned and used precision measurement devices.

Caliper gages are capable of measuring a range of distances, internal diameters, and external diameters. Micrometers tend to be more accurate in their measurements – however, they typically can only measure up to several inches.

While caliper gages are a slightly less accurate tool, they can take measurements as small as a couple of inches and as big as four feet.

One of the biggest disadvantages of the caliper gage is the lack of precision. The tool itself is built to be precise in each measurement, but to use it to its full ability, the operator must be very skilled. Positioning the tool properly and correctly interpreting the output can be a challenge for a novice.

With a more experienced operator, the caliper gage provides very consistent and accurate measurements. Caliper gages require recalibration about once a year and should be checked regularly for wear and damage.

What are the Parts of Caliper Gages? As with most precision measurement tools, the caliper gage has undergone some beneficial transformations over time. Since its first invention, this measurement tool has improved usability and accuracy.

- Electronic caliper gages of today can often connect to computer software, convert measurement units, and compare related measurements.

- Manual caliper gages are still very useful and are typically a cheaper option for those concerned with price.

The lower jaws on a caliper gage are designed to grip the object being measured. One of the lower jaws remains fixed in place while the other lower jaw moves along the measurement scale. The lower jaws are commonly used to measure the outer dimensions of a part such as diameter, length, or width.

The upper jaws on a caliper gage are much smaller and located on the upper portion of the tool. Similar to the lower jaws, one upper jaw is fixed while the other is free to move along the measurement scale. When measuring inside dimensions, the upper jaws are easily placed along the inside edges of the area.

The depth rod is a thin rod at the end of the main scale that extends in order to measure the depth of a hole or step. The main scale is the central large measurement scale on the caliper gage that runs along the tool body.

The main scale can have a millimeter or inch of graduations, and sometimes has both – it remains stationary during measurement.

On a Vernier caliper gage, there is also a Vernier scale that moves along the main scale in proportion to the movement of the jaws. The Vernier scale further divides the measurement units found on the main scale.

Finally, caliper gages come with two types of screws:

- The thumb screw provides a grip that helps the operator slide and adjust the jaws or depth rod.

- The lock screw on a caliper gage fixes the movable upper and lower jaws in place once the tool is positioned in order to take an accurate reading.

What Functions are Caliper Gages Used For?

Caliper gages are used for a number of different measurements across a variety of measurement settings.

These great tools can take measurements of:

- outside surfaces

- inside surfaces

- step measurements

- depth measurements

Additionally, the caliper gage is great for measuring distances. Caliper gages are used in a number of applied fields, such as:

- mechanical engineering

- medicine, science

- woodworking

- metalworking

- forestry

The greatest quality of the caliper gage is how many different measurement tasks it can be used for.

Caliper Gage Measurement Accuracy

Regarding accuracy, the general rule with caliper gages is that it is up to the user rather than the device itself. Given the incredible versatility of the caliper gage, this tool can be used to take any number of measurements.

However, in order to attain a high level of accuracy in these measurements, the individual using the caliper gage must be experienced in positioning and reading the tool. With that said, with increased levels of practice, almost anyone can learn how to use a caliper gage accurately.

Additionally, with the invention of electronic caliper gages, interpreting the output on a caliper gage became infinitely easier.

If you are newer in the metrology field or are just unsure of how to use a caliper gage, it will be beneficial to the level of accuracy you get if you use a digital rather than a dial caliper gage to start.

The electronic calipers still require a good amount of skill to position the tool and apply it to the various dimensions of interest.

There are two types of specifications to use when assessing the accuracy of a caliper gage that are the most important to consider. These characteristics include the partial surface contact error, also known as E, and the scale shift error, also known as S.

- The partial surface contact error refers to measurements made with the outside faces of the caliper gage.

- The scale shift error refers to measurements made with the other surfaces on the caliper gage.

- Any caliper gage you purchase can be assessed based on these specification values in order to help you understand the potential measurement error present.

Why Do Caliper Gages Have Different Contact Point Options?

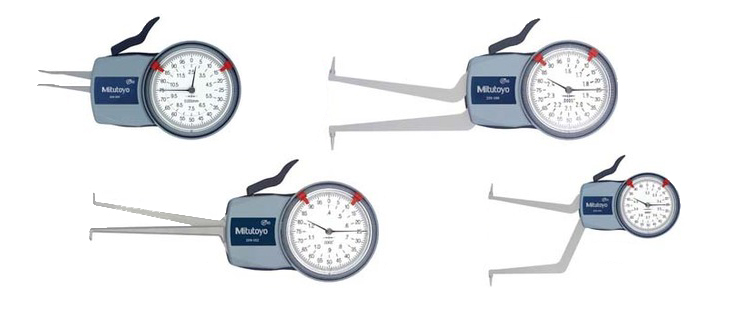

Inside diameter caliper gages

Inside diameter caliper gages, also called internal caliper gages, come in both dial and electronic versions. What makes this type of caliper gage different from the others is the placement and style of the jaws. The jaws on an internal caliper gage tend to be mostly straight with a slight outward curve at the end.

This design is intended for taking measurements on the inside surface of an object. In other words, the jaws on an inside diameter caliper gage are built such that the very tip of the jaw curves out so that these two tips are the only portion of the tool in contact with the part.

This provides the most accurate measurement of an inside diameter. The contact point option for an internal caliper gage is important for fitting the tool inside the area being measured which may be narrow or tight.

Outside diameter caliper gages

Outside diameter caliper gages, also called external caliper gages, come in both dial and electronic versions. What makes this type of caliper gage different from the others is the structure and design of the jaws. Each jaw on an outside diameter bows out in a square-like shape before coming back into the contact point. When at rest, the jaws of an outside diameter caliper gage are touching. Then, when in use, these points of contact can be placed on the external surface that you are trying to measure, providing the most accurate measurement from one external point to another. This design is meant specifically for measuring external distances on a part or object.

How To Use a Caliper Gage

Using a caliper gage, whether dial or electronic, requires practice, patience, and skill. The jaws of a caliper gage must be placed very precisely perpendicular, or square, to the object being measured. Holding the jaws firmly in place is important, but you must also be careful not to cause any deflection.

In general, the object being measured needs to be as close as possible to the frame of the caliper gage. Broadly, the use of a caliper gage requires approximately four steps:

- Holding the caliper gage using the thumb screw, position the fixed jaw on the inside or outside of the part being measured.

- Adjust the movable jaw such that it is then positioned on the opposite location, thus covering the space or area being measured. This is the same regardless of whether the upper or lower jaws are being used.

- Tighten the lock screw so that the position of the tool is stabilized and locked in place.

- Whether holding the tool in place or removing it once it is locked, read the measurement output either manually from the scale or digitally from the read out screen. Depending on the type of measurement you are taking, these steps will require more intricate sub-steps and adjustments.

How to Choose the Right Caliper Gage

Choosing the right caliper gage will depend on what types of measurements you need to complete using the tool. These versatile tools can measure outside diameter, inside diameters, groove thickness, tube thickness, and hard-to-reach dimensions.

The Best Caliper Gages for Sale

At Higher Precision, we carry some of the top brand caliper gages available. We provide a range of caliper gages from:

Whether you are looking for a particular style, brand, or price, we can help you make the best caliper gage purchase.

Understanding the Basics of Caliper Gages

The caliper gage is an incredibly useful tool that can be involved in a number of different settings to complete a range of different measurements.

These wonderful tools are capable of taking measurements of outside or inside surfaces, and can complete step measurements, depth measurements, as well as distance measurements.

In fields such as mechanical engineering, medicine, science, woodworking, metalworking, and forestry – caliper gages is a commonly applied tool. Despite its versatility, the caliper gage is most accurate when the user is proficient in handling and reading the tool.

Electronic or digital caliper gages can help minimize this error for more inexperienced users. Learning to utilize the caliper gage is a great skill and will come in handy in a variety of measurement contexts.

Call us today at Higher Precision to get some more information about the caliper gages we offer and to have all your caliper gage questions answered.

FREQUENTLY ASKED QUESTIONS

- What types of caliper gages are available and what are their differences?

- The broad categories of types of caliper gages include, digital caliper gage, dial caliper gage, external caliper gage, internal caliper gage, metric caliper gage, and inch caliper gage. Digital and dial calipers differ in build and output style. Some metrologists prefer to have more manual control over a measurement, and therefore may prefer a dial caliper gage that allows them to determine the output. Others might like the consistency offered by an electronic tool design and the digital output option. Internal and external caliper gages differ in what they are intended to measure. Internal caliper gages take inside measurements of an object, while external caliper gages take outside measurements. These calipers require gentle handling so as to avoid bending or damage during adjustment and positioning. Metric and inch caliper gages simply differ in the unit of measurement output. Most often, caliper gages are built as overlapping types rather than each one of these types being built independently. Caliper gages are commonly able to switch between metric and inch output and likely can manage both manual and digital measurements. Something to keep in mind when buying a caliper gage is that if you do not see a specific design feature that you have in mind, just ask. These tools come in a huge variety and there may be a way in which to create the specific caliper gage you are hoping for or to adjust another version to match the needs you have in mind.

- What are the benefits of using a caliper gage in precision measurement?

- The biggest benefit of using a caliper gage in precision measurement is the versatility of the tool. Caliper gages can measure any number of points of contact on a part or object, and has a much wider measurement range that similar tools. These great devices are able to be so flexible in measurement capability because of the hinged geometry technology used to build them. The jaws on a caliper gage have movement based on a gear within the pivot point, which can be re-enlarged by the same degree on the face of the tool. As long as a consistent 10:1 ration is maintained, you can adjust the jaws on a caliper gage to be almost any shape or size that you need. This allows the caliper gage to be used to measure distances, angled holes, flanges, curves, and hard-to-reach areas. While taking accurate and precise measurements using a caliper gage requires experience and practice, once you are well-versed in using these tools you can use them across so many different types of measurements. Having the skill to use a caliper gage is very useful to any metrologist.

- How can you test the calibration and verification of a caliper gage?

- Once you know the conformance standards and specifications that your caliper is supposed to align with, it is important for you to verify that conformance. One way to test the partial surface contact error conformance of your caliper gage uses gage blocks, a caliper checker, or another reference tool. Using at least three and at most five testing points, you will want to cover a minimum of 90% of the measurement range of the tool and to locate the reference standard tool along different positions of the caliper gage measurement faces. Testing the scale shift error conformance on a caliper gage similarly uses a caliper checker or gage blocks, but may also be done with a ring gage or surface face. What reference standard you use will vary depending on whether you are checking step, depth, or inside measurements. For guidance on choosing test points when calibrating and verifying your caliper gage, refer to the ASME B89.1.14. When doing this process with a used instead of a new caliper gage, just be sure to also check for wear and damage.

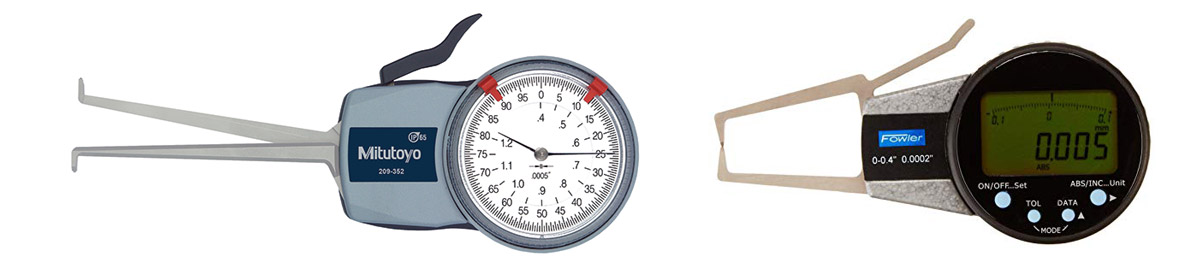

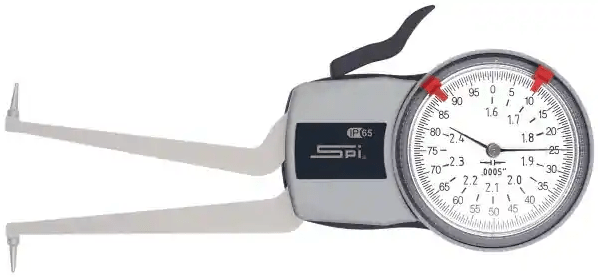

- What are some common brands of caliper gages?

- As a very common tool, you are likely to find a caliper gage under almost any precision measurement company brand name. Different brands may specialize in different caliper gage designs or sizes. At Higher Precision, we carry a huge selection of caliper gages produced and distributed by four of our favorite precision measurement businesses. We offer caliper gages from Mitutoya, Fowler, Spi, and Insize. Each of these brands offers standard caliper gages, dial caliper gages, digital caliper gages, internal caliper gages, external caliper gages, inch caliper gages, and metric caliper gages. If you need a caliper gage, we have one for you. It is just a matter of determining the best design for your intended precision measurement job.

GLOSSARY TERMS

- Caliper gage

- A caliper gage is a precision measurement tool that measures the distance between two opposing points on an object. Caliper gages come in a range of designs including a dial caliper gage, an electronic caliper gage, an internal caliper gage, and an external caliper gage. The caliper gage tool can be built to provide measurements in inches or metric units, and often is design to offer both types of units of measurement. The accuracy of a caliper gage depends a great deal on the skill of the operator. These tools are very versatile and can measure over a great distance and from a number of angles.

- Dial caliper gage

- A dial caliper gage is a particular design of caliper gage that must be operated manually. The measurement from a dial caliper gage must be read and interpreted by the operator and requires practice and experience. Dial caliper gages are great for making both direct and comparative measurements. Typically, the jaws of a dial caliper gage can slide past each other which allows for very small or narrow measurement dimensions.

- Digital caliper gage

- The digital caliper gage is a particular design of caliper gage that is often called an electronic caliper gage. With an electronic readout, the digital caliper gage is simple to interpret and can easily be connected to a computer system. Switching between metric and inch units on a digital caliper gage is simple, and zero setting has never been easier. A very durable version of the caliper gage, the digital caliper gage does not have moving parts in the readout and can withstand very tough environments.