We have certainly discussed anvil micrometers on the Higher Precision blog. But what about the slightly more obscure v-anvil micrometer? Well, it is time for the v-anvil micrometer to get a bit of the spotlight. This specialty tool provides precision in measurements when other tools just will not suffice. But we will get into that in a bit. First we would like to introduce you to the general design of the v-anvil micrometer so you can understand what we are referring to throughout.

The Design of V-Anvil Micrometer

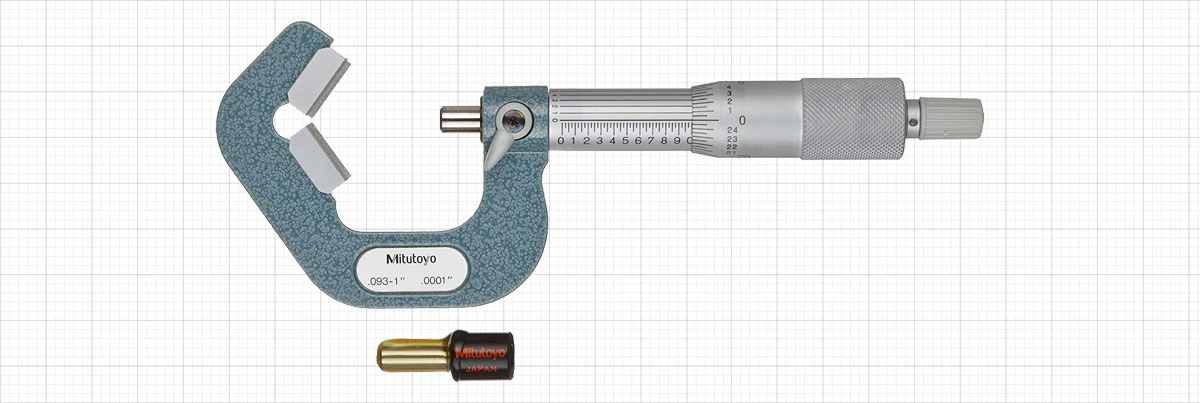

The v-anvil micrometer is similar in overall structure to the standard micrometer. The main parts include the ratchet, knurled gripe, thimble, sleeve, lock nut, c frame, spindle, and anvil. The difference that sets the v-anvil apart is the shape of the anvil itself, which is shaped like the letter “V” laying on its side. The v of the v-anvil itself comes with more widely distanced or close together tips, and the point where the two lines of the “V” connect can be touching and fused or may have a small gap between them. Finally, the end of the spindle may be flat across or be conical in structure with varying degrees of a point at the tip. All of these minor adjustments in design provide greater levels of precision based upon what it is you are using the v-anvil micrometer to measure. V-anvil micrometers also come with a ratchet stop in order to apply a more constant force and can be made with a centerline groove that provides further specialization of measurement. Finally, v-anvil micrometers come in both digital and Vernier styles. Benefits of using a digital v-anvil micrometer include having a precise zero-setting, data hold for ongoing measurements, a 2-point preset for more efficient use, a function lock to lock the position in place, clearer data output, and conversion capabilities between inches and millimeters.

Uses for the V-Anvil Micrometer

The v-anvil micrometer has two common uses. These include measuring the outside diameter of cutting tools that are built with an odd number of flutes and checking a part for roundness. We will describe both of these applications in more detail.

Measuring the Outside Diameter of Cutting Tools

When taking a measurement of outside diameter from a cutting tool with an odd number of flutes, it is difficult to use a standard micrometer or caliper given the uneven placement of the part surfaces used for measurement. This is where the v-anvil micrometer is particularly useful. Given the placement of the v-shaped sides of the anvil, a cutting tool with an odd number of flutes can be measured easily. Simply lay the cutting tool on its side perpendicular to the v-anvil micrometer anvil, align the lanes of the flutes up with the anvil surface and spin the ratchet to adjust the spindle into place. The v-anvil micrometer is ideal when measuring cutting tools such as taps, reamers, and end mills. Additionally, v-anvil micrometers are useful for measuring the pitch diameter of a tap that has a small diameter. This can be accomplished by the single-wire method. One important factor to keep in mind when measuring tools with odd numbers of flutes is that the number of flutes will determine the specific design of v-anvil micrometer that is required. For example, when inspecting a tool with 5 flutes you will need a different v-anvil micrometer than when inspecting a tool with 3 flutes.

Checking for Roundness

Another use for the v-anvil micrometer is to check for roundness of a part, also known as checking for out-of-roundness. The way in which this is done is to first take several measurements at different locations around the outside of the part cylinder or shaft. Then, you subtract the smallest diameter from the largest diameter. Finally, you divide the resulting number by two. The outcome represents the amount of out-of-roundness that the part exhibits. Checking for roundness is made easier by the v-anvil micrometer because of the location the sides of the v-shaped anvil are well-positioned to place a part horizontally and have contact points be around the edge.

Benefits of the V-Anvil Micrometer

The v-anvil micrometer increases measurement precision when collecting data on diameter because of the way in which the measurement is collected. Each diameter measurement is taken with contact made at three points (each side of the anvil “V” and the spindle). Having three points of contact is in contrast to the normal two points of contact available when using a standard micrometer or caliper. In fact, when working with cutting tools that have an odd number of flutes, the v-anvil micrometer remains the only device capable of taking a highly precise measurement.

Technical Data for V-Anvil Micrometers

Having some basic technical data regarding the design of v-anvil micrometers is helpful for those hoping to understand the details of application. V-anvil micrometers are available with or without a centerline groove. Having a centerline groove can be helpful when taking the measurement of pitch diameters on taps that have three or five flutes. The zero reading of the v-anvil micrometer always starts from the point where the two sides of the “V” meet. Often, the v-anvil micrometer will come pre-equipped with a cylindrical zero set check. On analog models, graduation is 0.01mm, .001mm, or .0001mm and flatness of the spindle and anvil is 0.6µm[.000024”] /1.3µm[.00005”]. On digital models, flatness of the spindle and anvil is 0.3µm[.000012”] /1µm[.00004] and the battery life can be expected to last 1-2 years with normal usage. The resolution of the digital models is typically 0.001mm or .00005″/0.001mm. Functionally, a digital v-anvil micrometer has a zero-setting, data hold, function lock, data output, 2-point pre-set, and conversion capabilities.

Conclusion

V-anvil micrometers are just the tools you need for very specific precision measurement tasks. When working with an odd number of flutes on a cutting tool or checking for out-of-roundness, these tools will provide the measurements you require with ease. While they may not be as versatile as the standard micrometer or caliper, v-anvil micrometers are a requirement for any metrologist tool set. Contact us at Higher Precision to learn more about the styles of v-anvil micrometer we offer and which one will provide you with the most accurate output.

FREQUENTLY ASKED QUESTIONS

- What is the design of the v-anvil micrometer?

The v-anvil micrometer is very similar in design to the standard micrometer, with the main important difference being the shape of the anvil itself. On a v-anvil micrometer, the anvil is shaped like a “V” that is laying on its side and therefore perpendicular to the shaft of the micrometer. Tips of the “V” on the v-anvil micrometer may be closer together or further apart, and the spindle end may be pointed like a cone or be flat across. Finally, the bottom of the “V” anvil may have the sides meet together and be bonded or may have the sides be separated by a gap. Depending on the specific type of measurement you are hoping to accomplish with a v-anvil micrometer, these various design specifications can make a big difference. V-anvil micrometers are also available in either analog or digital design formats. While some prefer the control allotted by the analog, others like the precise nature of digital readings. On analog models, graduation is 0.01mm, .001mm, or .0001mm and flatness of the spindle and anvil is 0.6µm[.000024”] /1.3µm[.00005”]. On digital models, flatness of the spindle and anvil is 0.3µm[.000012”] /1µm[.00004]. Digital models come with a few additional features that may prove beneficial: ability to convert units, a 2-point pre-set, a zero-setting, function lock, data hold, and data output.

- What is the v-anvil micrometer used for?

The two main uses for the v-anvil micrometer are measuring the outside diameter of a cutting tool that is built with an odd number of flutes (typically three or five) and measuring out-of-roundness on the exterior of a part. In measuring diameter on a cutting tool with an odd number of flutes, the v-anvil micrometer is designed to account for the off placement of the surfaces used for measurement. In order to complete this measurement, you lay the cutting tool on its side, perpendicular to and across the “V” anvil. Once the lanes of the flutes are lined up with the side surfaces of the anvil, put the spindle into place using the ratchet and you are good to go. When measuring out-of-roundness, the v-anvil micrometer creates the optimal spacing to accomplish this task. After measuring multiple points along the outer surface of a part, subtract the smallest measurement from the largest and divide the resulting number by two. This provides you with a measurement of out-of-roundness. V-anvil micrometers can also be used to apply the single-wire method to measure the pitch diameter of a smaller tap.

- What makes the v-anvil micrometer ideal for specific measurements?

The v-anvil micrometer is ideal for the specific measurements described – outside diameter of cutting tools with an odd number of flutes and part out-of-roundness. What makes the v-anvil micrometer such a specialized precision measurement tool is the shape of the anvil into a “V”. The shape of the anvil on the v-anvil micrometer allows for three points of contact as opposed to the two that are available when using another type of micrometer or caliper. These three points of contact include each side of the “V” as well as the spindle. The increase in contact points allows for more accurate and stable positioning of the part or tool being measured which increases the precision of the overall measurement. In fact, the v-anvil micrometer is the only precision measurement tool capable of completing these types of measurements with that level of accuracy.

GLOSSARY TERMS

- V-Anvil Micrometer

A v-anvil micrometer is a specially designed micrometer ideal for measuring the outside diameter of cutting tools with an odd number of flutes and for assessing the out-of-roundness of a part. The anvil of the v-anvil micrometer is shaped like the letter “V” laying on its side and comes with more widely distanced or close together tips. The point where the two lines of the “V” connect can be touching and fused or may have a small gap between them. Each differently designed v-anvil micrometer is built in such a way to take particular and precise measurements.

- Tap

A tap is a tool that can be used when building screw threads. A form of cutting tool, a tap forms the female portion of the mating pair used to later combine parts. When using a tap to cut the threads on a screw, the process is called tapping. Taps are difficult to measure given the off number of flutes. Due to this, a v-anvil micrometer is the best device to use when taking measurements of a tap.

- Reamer

A reamer is a particular kind of cutting tool that is used for widening or finishing drilled holes. Designed to leave the sides of a hole smooth, a precision reamer has a high degree of accuracy. Reamers are made with a set of parallel and straight or helical cutting edges all along the side of the cylinder-shaped body. When helical, the spiral down the reamer can follow either a clockwise or counter clockwise design. The odd number of flutes that can be found on a reamer make these tools best measured using a v-anvil micrometer.

- End Mill

An end mill is a specific type of milling cutter which is used in the process of removing material with rotary cutters. Able to cut in a radial direction, the end mill is designed in order to cut axially as well. The end mill is commonly used in face milling, profile milling, and tracer milling. End mills are categorized based on the style of cutting they do, number of flutes they have, the helix angle when applied, and the material they are made of. End mills, when built with an odd number of flutes, are best measured using a v-anvil micrometer.