When it comes to precision measurement, the dynamic duo of accuracy and repeatability always seem to come as a pair. While arguably they are equally important, today we would like to focus on the concept of repeatability and why it is so important in the field of metrology. Repeatability relates strongly to the precision of a measurement. Here at Higher Precision, we find precision important enough to include it in our name. Let us tell you why.

So, what exactly is repeatability? Repeatability is the degree to which numerous measurements taken successively, under identical conditions, agree in outcome value. In other words, repeatability refers to how close a series of measurements of a single item or area are when taken in a row, using the same tool or machine, and when conducted by the same operator. Another term for repeatability is test-retest reliability; when you retest or re-measure an item or area, you get essentially the same output. When the same measurement is not achieved, therefore when a tool or device is not reliable, then we say that there is variability. Variability can be caused by the quality of the measurement tool being used, the lack of calibration of the measurement tool being used, the operator using the tool, or contextual factors like room temperature or stability of the item being measured. A repeatable measurement indicates that the operator will get the same measurement value each and every time the measurement is taken.

So, why is repeatability so important? Measurement in and of itself is almost always a small portion of a bigger project. Whether you are checking alignment, size, irregularities, or standards of a part, that part will end up a piece of a bigger end product being built. Whether you are machining, assembling, cutting, or adjusting a part, that part will need to be incorporated into the bigger end product being made. Measurement may just be a small step in the creation of the final device, machine, or product, but if the measurements taken are not reliable then the eventual manufactured piece will not be reliable either. Variance in measurement will result in irregularities in the end product. Above almost all else, you want to have repeatability in your measurements to ensure you are taking precise measurements. In this way you are guaranteeing quality in your process and your outcome.

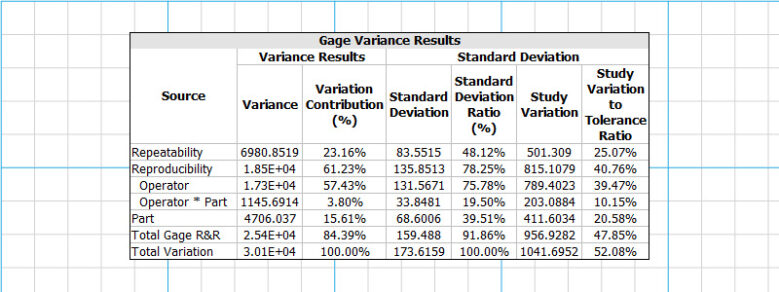

A repeatable measurement is a consistent measurement, and more often than not, metrologists rely heavily on consistency for ultimate precision. One way in which to help check, maintain, and guarantee repeatability of your measurements is to conduct repeatability tests. A repeatability test is specifically designed to check the repeatability of one person, one device, and one part, in one environment. You will want to start by calibrating the measurement device or tool you are using in order to conduct the test. Then you will want to define a certain set of factors that will remain constant throughout the test. These include: what you are measuring, the equipment you are using to take the measurement, the planned date, the operator, the method of conducting the measurement, the specific environmental conditions, and the amount of data you want to collect. In general, the more data you collect, the better. After collecting data, you can analyze a range of descriptive statistics in order to assess the repeatability of your measurement process. Regularly conducting repeatability tests is a good idea for any measurement facility.

Repeatability must be paired with accuracy for an ultimately precise measurement. However, repeatability is incredibly important for precise measurements in its own right. We wanted to highlight for you what repeatability is, why we at Higher Precision find it so important, and why we think you should too.