Rules, also known as rulers, are possibly the most basic measurement tool, and they are certainly a best seller. Whether you are an expert metrologist designing spaceships, or a second-grader working on an art project, you might end up needing a rule. While they are simple in principle and application, rules come in different types and have certain advantages and disadvantages that are important to consider. Today, we would like to provide you with an overview of these widely used tools and offer some important information concerning how they vary and how they ought to be used.

Most basically, a rule is any straight edge tool that has graduated markings that allow for absolute measurements. The first important factor to keep in mind when choosing a rule is to make sure that the measurement system matches the type of measurement you are aiming to complete. Do not use a metric ruler to measure inches. Additionally, you want to determine what graduations are necessary to complete your measurement. Graduations are the markings on the measurement tool itself that evenly divide up the space of the scale, and can be curved like on a protractor or straight like on a rule. If your measurement requires more finite measurement increments, you will need different gradations than when you are getting a rough estimate of a length. Graduations are commonly known using different type names such as 3R, 4R, 9R, and many more. These names signify the increments of measurement that can be found on that particular rule. For example, a 3R rule measures in 10ths and 50ths on the front and 64ths and 32nds on the back, a 4R rule measures in 8ths and 16ths on the front and 64ths and 32nds on the back, and a 9R rule measures in 16ths and 32nds on the front and 64ths on the back.

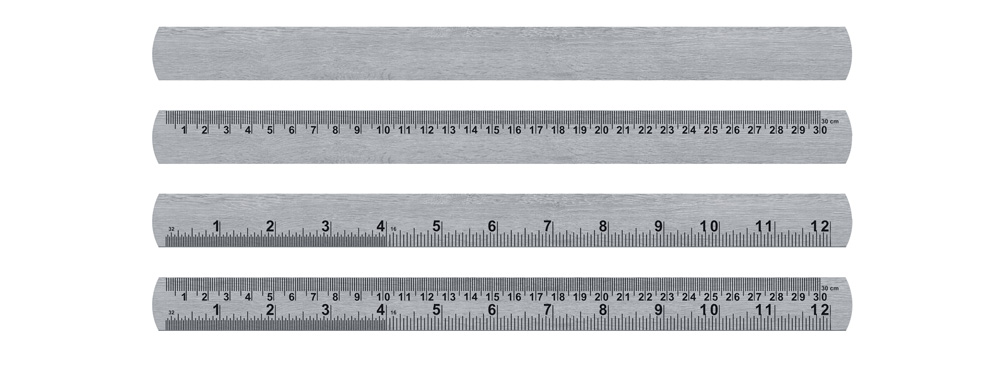

Rules themselves come in different types, styles, and materials. A rule can be made from wood, plastic, or metal. Metal rules tend to be more long-lasting and accurate than wooden rules, but some wooden rules are reinforced with a metal edge. The graduations on a rule can be etched, scribed, engraved, painted, or printed onto the tool. The method of marking graduations that is used in combination with the ruler material will result in variations in durability and precision. Another feature of a rule to consider is length and width. In order to take an accurate measurement, measuring objects shorter in length than the rule you are using is important. Risk of imprecision increases greatly when you need to move the ruler and mark a new zero point in the process. If you are regularly outside of your workspace, a smaller rule may be helpful for transportation. Shorter rules are also good for measurement in confined spaces. Thinner rules may be important for hard to reach areas or narrow spaces. Finally, rules can be either flexible or rigid. Flexible rules can be used to measure around a solid body or part and come in a range of flexibilities. A typical steel rule will be slightly bendable whereas a measuring tape is able to be wound around an object or corner. A rigid rule is useful when you do not want any movement of your rule when measuring. The material, size, and flexibility of the rule you need greatly varies depending on the work you are completing.

The five main types of steel rules are spring-tempered, flexible, narrow, hook, and short-length. Spring-tempered steel rules are usually six inches in length and made for quick measurements. Flexible steel rules are what many of us think of as a tape measure. They are typically used for construction or around the house. The narrow steel rule, as mentioned above, is ideal for reaching tight and hard to access places. The hook steel rule is built with a hook on one end meant to be placed against a corner or protrusion to provide stability during measurement. Finally, short-length rules are small rules that come in sets of four and range in sizes, generally used to measure small parts or openings.

As possibly the most common and basic measurement tool available, the rule has a surprising number of details and types that impact measurement. Rules rely entirely on user experience and objective reading. You want to be very careful to choose the best rule for the measurement you intend to do because the different materials, sizes, and flexibilities greatly impact both accuracy and precision.

Shop our selection of Rules today