For this month’s blog, we would like to talk about Inspection Arsenal®, a light duty inspection fixturing system, by Phillips Precision’s Products Division. We are really excited about what Inspection Arsenal® has to offer. This quick-swap modular inspection fixture system is going to completely change your inspection process for the better. Saving you time, increasing your precision, and boosting employee satisfaction are only a few of the ways that Inspection Arsenal® can upgrade your precision measurement experience. We all know that quality inspection is at the heart of successful manufacturing. With the expansive technology available, the possibilities within the metrology field seem endless. However, it is crucial to not overlook the more foundational components of measurement, such as fixturing. Inspection Arsenal® is a one-of-a-kind flexible pallet system that has honed in on the inspection process and offered a way to completely streamline its function.

Difficulties of the inspection process

The shop floor in any manufacturing plant is built around production and the required fixturing to keep spindles turning. The success of each shop relies heavily on the workers at the center of the inspection process. However, we are all only as capable as the tools at our disposal and inspectors are often hindered by the methods of yesteryear, used to test and inspect various parts. Additionally, there is a great deal of responsibility put on the shoulders of inspectors to ensure parts are sent out according to the required standards, consistently time after time. The typical process of inspection likely involves a considerable amount of development, assembly and reassembly of fixtures, putting the inspectors behind from the start.

Inspection labs can use the fanciest technology in the world, but without proper fixturing, the outcome of all subsequent steps is impacted. You may be used to one-piece grid plates for work holding. However, this style of fixturing requires constant set up and breakdown, just to use the same fixture again later or to develop a setup for a new part for inspection. The assembly and staging of parts is limited to the machine’s downtime. This slows down the entire production process, all the way back to idle spindles on the shop floor waiting for inspection data.

How Inspection Arsenal Works

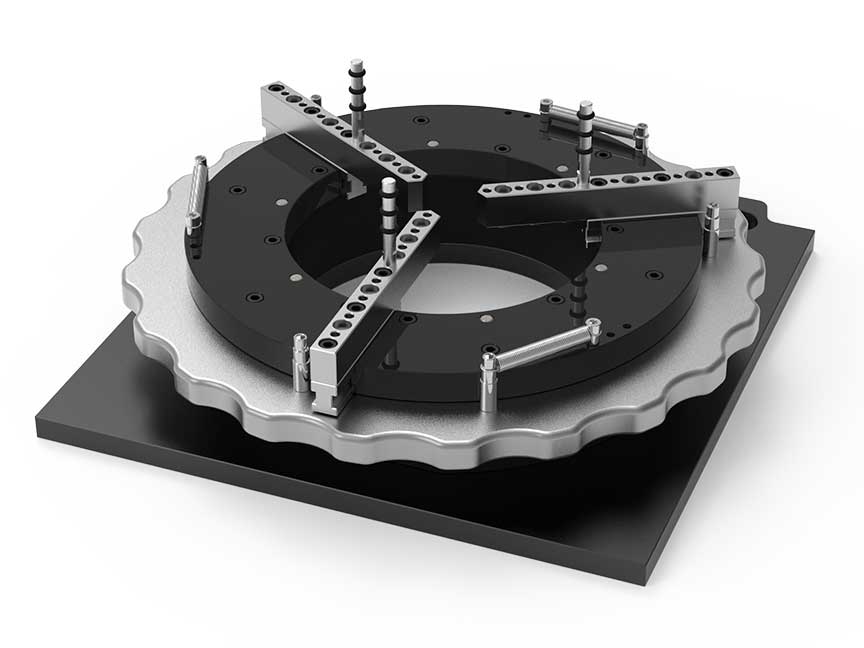

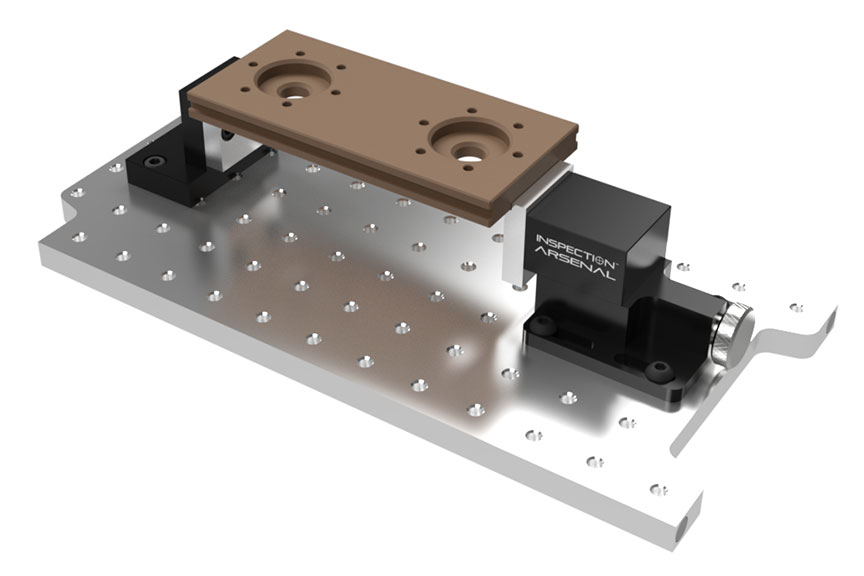

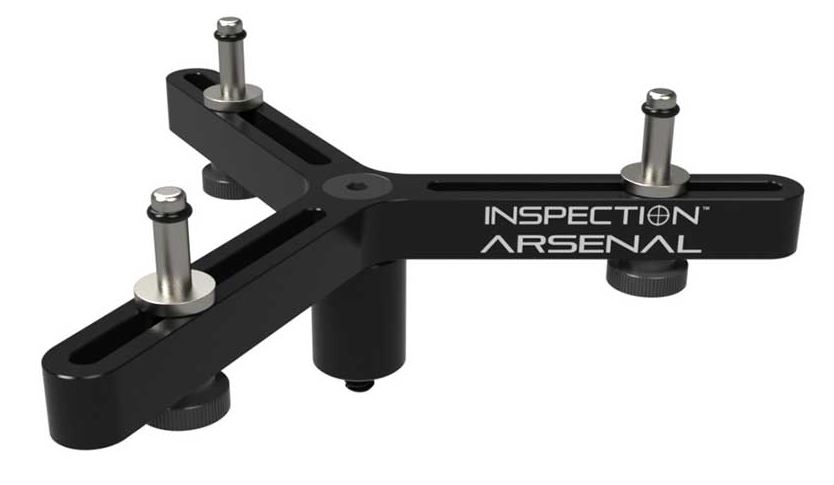

Do not fret, for a solution exists! Let’s talk about Inspection Arsenal®. Inspection Arsenal® is a versatile and flexible modular quick swap fixturing system, allowing you to adapt to your specific fixturing needs.. The Docking Rail can be mounted on the x-axis, the y-axis, or both; on CMM machines, vision systems, optical comparators and portable gage arms. You can also run a series of rails across the measuring surface, in order to provide numerous locations to load fixtures as needed. Designed to be used across all types of inspection equipment, the Inspection Arsenal® fixturing is extremely versatile and built to fit into your already existing workspace. Parts can be easily fixtured and then loaded onto one machine or swapped between multiple machines, improving efficiency and guaranteeing accuracy following relocation. Inspection Arsenal® fixtures are easily disassembled, stored, and reassembled when needed. But, if you are running production parts, or inspecting the same parts again and again, why waste time and effort when you can use the modular power of Inspection Arsenal®? You can take the entire, fully assembled fixture off of your machine to store away when not in use. Even newer operators or those working to improve their skill level can easily maintain reproducibility and repeatability when working with this system. The Loc-N-Load™ plates are made with both ¼-20 and M6 holes which ought to work with current tooling and fixturing you already have at your disposal.

Benefits of Inspection Arsenal

Every time a fixture is rebuilt, it runs the risk of inaccuracies or slight alterations in design. Even when following instructions or images, these risks are present due to various factors such as different users or unnoticed changes in reassembly. The potential for tiny deviations in this process can lead to inaccuracies in inspection data, thus having a cascading effect on subsequent production. Inspection Arsenal® provides a system that makes repeatability and reproducibility simple. By setting up each fixture independently from the machine, this inspection system allows you to remove and swap fixtures with minimal downtime and zero error.

Customizing your Inspection Arsenal

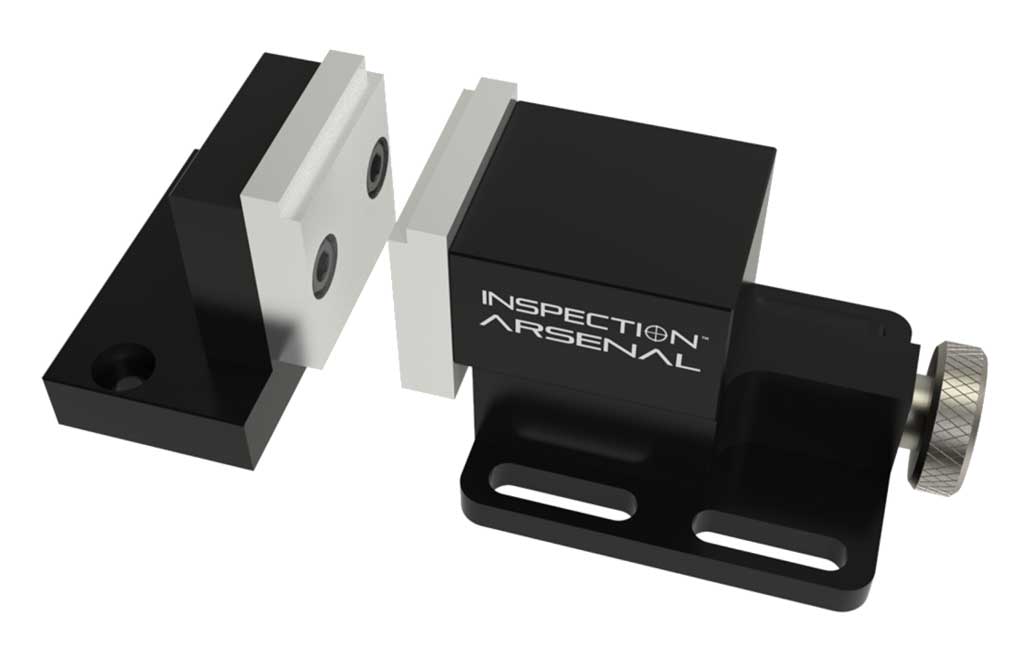

Inspection Arsenal® also offers adaptor plates that are designed to help transform your custom or dedicated fixtures into Loc-N-Load™ fixtures. With available CAD models, Inspection Arsenal® fixtures can also be developed simultaneously with the shop floor fixtures in order to eliminate downtime typically lost when inspection is an afterthought. All fixturing can be made completely customizable based on need. Browse the CMM, Vision System, Gage Arm, zCAT, and Optical Comparator fixture bundles. Plus, fixture plates, docking rails, accessory plates, work holding, and a range of specialty clamps and vises are available a la carte, for the most versatile fixturing options.

Rethinking your inspection process with Inspection Arsenal

When you rethink your inspection process with Inspection Arsenal®, you are opening yourself up to several improvements at all stages of the manufacturing process. You will increase your bottom line by decreasing the down time between inspections. Without the need to break down and reassemble your fixtures with each inspection, Inspection Arsenal® allows for easy setup, breakdown and storage of individual Loc-N-Load™ fixtures. You will build yourself a respectable reputation for delivering perfect parts every time, and fast. Finally, and certainly not least, you will see a boost in employee morale, because with Inspection Arsenal®, the inspection process becomes less tedious, faster and more reliable. Helping to support your employees in doing their job better and more efficiently.

Conclusion

We love being able to highlight ways you can improve your production output and we believe the Inspection Arsenal® is one of the best innovations in recent metrology. Any manufacturing process is only as good as its foundation and by converting your inspection set up to Inspection Arsenal®, you are creating one of the strongest foundations possible. Increase your throughput and improve employee happiness by shifting over to the reliable and flexible Inspection Arsenal® fixture system. Contact us at Higher Precision today to learn more about how Inspection Arsenal® can help you.

https://inspectionarsenal.com/

FREQUENTLY ASKED QUESTIONS

- What is Inspection Arsenal?

- Inspection Arsenal is an inspection fixture system that is made up of lock-and-load interchangeable setup pallets that allow for fast, easy, and consistent inspection processes. Offering an affordable option, Inspection Arsenal is simple to learn and effective across numerous applications. These quick swap and interchangeable plates will speed up the productivity of your inspections without risk of losing of accuracy. This inspection system uses loading rails that accommodate mounting on the x or y-axis, or both. These fixtures are versatile and can be added to an existing workspace and applied across CMMs, vision systems, and optical comparators. Parts can be affixed to each Inspection Arsenal fixture and then moved, stored, or swapped between machines. The Inspection Arsenal system will help improve efficiency and accuracy, all throughout the measurement system.

- What are the benefits of using Inspection Arsenal?

- Inspection Arsenal will benefit your operation with greater efficiency, higher reliability, improved reproducibility, and increased employee satisfaction. As the foundation for all subsequent measurements, the initial and repeated inspection of a part or machine is crucial to all the events that follow. Using the incredible modular system of Inspection Arsenal will introduce flexibility and efficiency. By decreasing the downtime between inspections and measurements, Inspection Arsenal increases your bottom line. Additionally, return on investment will increase and speed up due to the improved efficiency of each step of your production process. You will show your partners and customers that you can deliver perfect parts at an unbeatable rate, without sacrificing accuracy or precision. All of this will work together to ensure employee satisfaction given how much the Inspection Arsenal setup can improve the actual work being completed.

- How can I customize Inspection Arsenal to fit my needs?

- Essentially every aspect of the Inspection Arsenal system can be customized to meet your needs or to convert your current set up to an upgraded experience. Each fixture plate can be designed with both quarter-twenty and M-6 holes, pairing well with current tools and fixturing you already have. You can browse the numerous parts to customize online and view within inch or metric systems. There are numerous fixture bundles built for CMM or vision fixturing. You can specify your need for a gage arm, zCAT, or Air-Glide extensions. With numerous accessory fixture plates and rails, Inspection Arsenal is highly adaptable to each metrology context. There are Open-Sight fixture bundles, optical comparator fixture bundles, as well as specific work holding components such as spring clamps, hold downs, stops, rails, standoffs, risers, modular tower systems, and cross members. Additionally, you will find a range of specialty clamps and vises that will further upgrade your personalized Inspection Arsenal system. These include Collet Chucks, Rapid-Loc Pneumatic, Skinny-Vise, Spanner-Vise, Sturdy Lever Clamp, Trigger-Point Lever Clamp, Spider-Clamp, Riser-Grip, and Spring-Load Chuck.

GLOSSARY TERMS

- Coordinate machine measurement (CMM)

- Coordinate machine measurement fixtures, also known as CMM fixtures, are the tools used to hold parts or workpeices in place during various measurement operations or inspections. CMM refers to the highly structured build of plates and fixture systems required for adequate consistency within the important process of inspection.

- Inspection

- In the field of metrology and precision measurement, inspection includes the procedures or activities that encompass maintaining certain standards for manufactured parts and measurement processes. Inspection can involve hardware, software, and guidelines that all work together to insure that parts are meeting characteristics they are expected to meet. The ultimate goal of inspection is for all products and workpieces to have guaranteed functionality and thus consistent value.

- Inspection Hardware

- Inspection hardware is any physical tool or device used to successfully conduct a functional assessment of a part or product. The inspection hardware is the actual measurement device used for the process of inspection and can be applied to an entire inspection process or be just a small step along the way to full inspection. Examples of inspection hardware include coordinate measurement machines, optical comparators, a calibrated tool, a roughness tester, or a system such as Inspection Arsenal.